Grand River Aseptic Manufacturing Completes Phase II Expansion with Installation of Two New Sterile Filling Lines

Grand River Aseptic Manufacturing (“GRAM”), a prominent parenteral drug product contract development and manufacturing organization (CDMO), has completed Phase II of its facility expansion which includes the installation of GRAM’s two new sterile Bausch+Ströbel filling lines. Now, with a total of three separate fill lines, GRAM’s filling capacity reaches over 50 million units per year with space to serve a greater variety of pharma and biotech customers. GRAM’s continued growth positions the company to become a leader in biotherapeutics with many new biologic capabilities and clients.

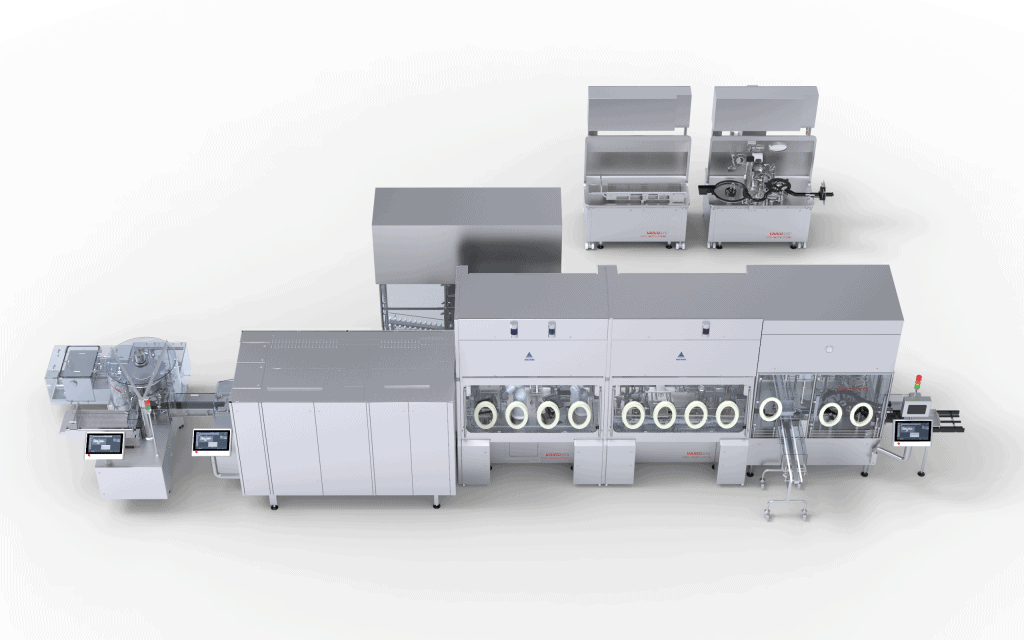

GRAM’s state-of-the-art aseptic filling facility is specifically designed with independent formulation and filling suites, and equipment that utilizes the latest pharmaceutical production technology to maintain the highest quality standards for clients’ drug products. Working closely with OEMs (original equipment manufacturers) on selecting the new equipment, GRAM installed a Bausch+Ströbel VarioSys® modular vial and syringe/cartridge fill line with SKAN isolator. In addition, GRAM installed a second Bausch+Ströbel high-speed vial fill line with SKAN isolator, identical in technology to the previously installed fill line with IMA lyophilizer, which began manufacturing product in September 2020.

“GRAM has assembled a team of experts within our company to serve new and existing partners on industry-leading equipment that elevates the breadth of what a CDMO can provide,” said Tom Ross, President and CEO of Grand River Aseptic Manufacturing. “Continuity of technology across all our fill lines benefits our clients as their products transition from the clinic to the market. The capabilities established at GRAM with new facilities and equipment will better serve our clients focused on high-value biologic drug products. We are excited and ready to offer top-of-the-line solutions to the marketplace and entertain even more guests here in Grand Rapids.” GRAM is currently taking on new clients and has initiated multiple tech transfer projects for vials, prefilled syringes and cartridges.

In addition to completing Phase II, GRAM has significantly progressed Phase III of their facility expansion, announced on April 28, 2022. This latest expansion will offer more filling and finishing capacity, and capabilities to the biopharma industry and should be complete in 2024. Mr. Ross noted, “The significant investments GRAM has made in the past three years have created a platform of brand-new facilities and technology. GRAM’s portfolio of solutions-based services continues to grow, and we look forward to an exciting future.”

About Grand River Aseptic Manufacturing, Inc.

Grand River Aseptic Manufacturing, Inc., a prominent parenteral drug contract development and manufacturing organization with advanced technology, delivers customized solutions to meet clients’ fill and finish needs from development through commercialization. With capabilities for biologics, small molecules and vaccines, Grand River Aseptic Manufacturing’s elite equipment and staff supports pharmaceutical development and cGMP manufacturing, analytical testing, and regulatory filing.