The Importance of Primary Containers in Drug Delivery

Whether a wearable device, a pen, or an auto-injector, the primary container that holds the drug product is crucial.

Listen to the podcast or read on for insight from Fierce Pharma and Mary Lou Glotzbach, Sr. Manager, Drug Delivery Partnerships at Grand River Aseptic Manufacturing.

With the growing biologics pipeline, what do you see as it relates to the needs of pharma and biotech companies?

One of the consistent messages we are hearing is that patients today often go to infusion centers for their drug treatments. A key goal for many companies is to transition these patients from infusion centers to home delivery and self-administration.

When working with biologics, we deal with large molecules and high-concentration products that need to shift from a large volume to a smaller volume. Companies are currently navigating the challenge of increased viscosity, which transpires from smaller volumes and higher concentrations. Essentially, the more concentrated the product, the more viscous it becomes, which can lead to the necessity of reverting to a higher volume.

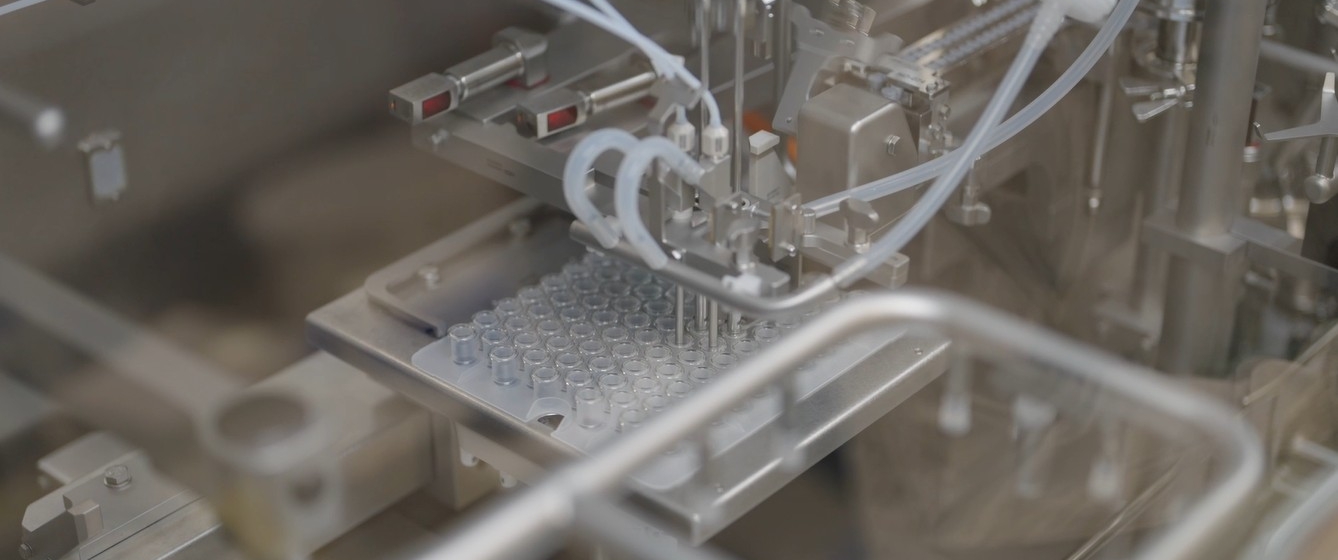

Pharma and biotech companies need a higher-volume contract development and manufacturing organization (CDMO) capable of filling their products into larger primary containers while simultaneously managing the requirement for a more viscous product. The industry is shifting towards using syringes or cartridges rather than vials to facilitate home delivery. This transition moves away from delivering the drug in 1 mL or 2 mL syringes to using a 5 mL primary container, typically in a cartridge format.

A notable trend is the request for biologics to be filled in larger volume containers, such as cartridges, which also handle slightly more viscous products. Another consideration is that biologics tend to be expensive to manufacture, and the drug substance itself is often challenging to produce. Consequently, these companies provide us with batch sizes that can range from 100 liters to 200 liters, which contrasts with small molecules that might require batch sizes closer to 500 or 1,000 liters.

We are approaching our commodity vendors for smaller syringe and cartridge batch sizes to accommodate these new requirements. CDMOs can no longer keep millions of units on a shelf while waiting for the next batch; instead, the next batch may only consist of around 10,000 units. This shift towards smaller batch sizes is another challenge introduced by biologics.

Additionally, pharmaceutical companies have strict requirements for maintaining the integrity of the molecule throughout the cold chain process. It is essential to manage the drug substance at -80°C and maintain this temperature throughout manufacturing. After being formulated in a tank and filled into a cartridge or syringe, the product must be packaged and undergo visual inspection, ideally remaining as cool as possible during all steps. Effective cold chain management is critically important for the handling of biologics.

What are some interesting changes to CDMO processes that you have experienced this last year?

Regarding the process, one significant trend we’ve observed is in the initial request for information (RFI). In this stage, the pharmaceutical company learns about your capabilities as a CDMO and evaluates whether your services match their needs. If there’s a match, you advance to the Request for Proposal (RFP) process. Traditionally, these RFIs and RFPs came primarily from large pharmaceutical companies. However, in the post-COVID world, we’ve noticed that smaller and medium-sized companies are also engaging in the RFI process. We’ve been receiving a lot of RFIs, which is encouraging. It’s essential to do your homework and ensure your CDMO capabilities align well with their needs before progressing to the proposal and site visit stages.

Another positive change is the emergence of calls from pharmaceutical companies’ device teams for product development opportunities. Previously, procurement or alliance teams typically brought opportunities to us. Now, CDMOs are being involved earlier in the discussions, allowing us to engage with the development team from the start.

This early collaboration is beneficial because it allows us to address any potential issues before they become significant problems. For instance, we might highlight that a particular product is not feasible for the required volume or assist with formulation challenges.

It’s exciting to receive calls from a pharmaceutical device team asking how to incorporate a drug product into an auto-injector, seeking our expertise on feasibility. These types of discussions are increasingly common today, and it’s a significant evolution in our industry, compared to the traditional model where pharmaceutical or biotech companies would develop a process and then hand it off to a CDMO without any prior consultation.

If you were in Pharma’s shoes, what would you bring to the table for discussion that maybe 10 years ago you wouldn’t have thought?

Annex 1 is the most significant aspect of our operations. We focus on ensuring we can deliver your product to market wherever it needs to go. Annex 1 compliance is critical when pharmaceutical companies approach us for discussions around our capabilities. It goes beyond merely presenting a PowerPoint showcasing our readiness for Annex 1 compliance. Instead, we thoroughly discuss our experiences, asking questions like, “How have you managed various challenges in the past?” and “What has it been like in real-world situations?”

These conversations dive deeply into the issues we face rather than just ticking off items on a checklist. Companies want to partner with a CDMO that is genuinely prepared for the complexities of the process.

When we compare our approach today to what we did ten years ago, transparency stands out as a significant change. In the past, pharmaceutical companies may not have felt comfortable sharing the hurdles they faced during production. The collaboration was often limited to merely transferring information and responsibilities. Now, we have regular, open discussions with our clients, effectively becoming part of their teams. This increased transparency allows us to share insights about our mutual challenges and collaborate more effectively to ensure their products are delivered on time and to specifications.

Without this level of transparency, we could face issues that might remain unresolved for months—something we aim to prevent. As part of fostering this transparency, we are increasingly signing confidentiality agreements that involve multiple parties, such as the client, the CDMO, syringe vendors, and container closure vendors. These agreements facilitate open communication among everyone involved, allowing us to effectively strategize to guide our clients and their products to successful outcomes.

Communication, coordination, and collaboration are key to achieving our goals.

What are some challenges for CDMOs when device companies launch a new on-body delivery system or auto-injector?

I always find it interesting at trade shows when visitors approach a booth for a company launching a new device, yet they never open it up. For me, what matters most is what’s on the inside.

When you encounter a wearable device, a pen, or an auto-injector, the primary container that holds the drug product is crucial. It’s important not to overlook that primary container. So, when collaborating with a device company or considering a new device, discuss details such as: What is the syringe like on the inside? What about the stopper? How will these elements work together? Have you worked with those vendors before? And who will be responsible for the filling process?

Even if you have a syringe and a stopper, you need to ensure that you have the right capability to fill it. If a device manufacturer is not working directly with a CDMO, they might face a steep learning curve once the project progresses—it’s better to have these conversations upfront.

Device manufacturers sometimes make assumptions about our capabilities. For instance, they may talk about viscosity and how great it is that their device can deliver a viscous product to the patient. However, if CDMOs cannot fill that viscous product into the primary container, it won’t matter what the device is designed to do. Early discussions about our capabilities and how we can assist are essential.

There is a lot of energy surrounding new primary containers, such as 10 mL and 20 mL options. If a device company opts to create a custom primary container that perfectly fits their device but does not consult with a CDMO early in the development process, they may encounter significant delays. If they bring the design to us too late, we might have to order special parts to accommodate the filling, which could extend their timeline by up to a year. Early communication is vital.

How is GRAM leveraging the power of collaboration with device partnerships to improve client service?

It is a pretty exciting time for collaboration and partnerships within our industry. A lot is happening regarding discovery, patient-centric delivery options, and bringing the patient to the forefront. Parties are all coming together with a flexible mindset to ensure success from the start.

GRAM has established outstanding partnerships characterized by transparency and mutual learning. When we work together toward a common goal and address issues openly, we can create a successful product for our shared client. Early in our collaboration, we discuss our capabilities and each other’s goals to ensure alignment. If our objectives don’t match, we explore how to move forward as a unified team rather than separate companies. As long as we communicate upfront and collaborate toward a shared goal, both parties can achieve success, which ultimately benefits the client.

What happens if we come together but are not moving in parallel, particularly with smaller volumes? If those volumes become standardized, would you consider that progress?

Imagine receiving a request for proposal that includes a standard 10 mL cartridge—if it’s ISO standard size, it wouldn’t matter whether the cartridge comes from this vendor or that vendor; our parts would be interchangeable.

We have been working with various vendors on smaller batch sizes, and it is truly happening. We are collaborating closely with commodity vendors and device companies, leading to greater transparency in the market. This enhances the overall effectiveness of the process. By avoiding duplicated efforts, we are genuinely making progress. There’s a lot happening in terms of discovery, with many promising drug products and delivery systems. Vendors are coming together and engaging in discussions, making this an exhilarating period for all involved.